Products

Products

● Suitable for food, feed, metallurgy, mining, ports and other industries, conveying density of 05-25m3 of a variety of bulk, finished materials. ● Can be arranged in a horizontal or inclined form. ● Large conveying capacity, simple structure, convenient maintenance and low cost. ● There are groove, flat, air cushion and other forms of belt conveyor to choose from. Model output (m3/h) Remarks TDSC50080-2301 and power are calculated according to output and length; 2. The output is TDSC650130-400TDSC800280-800TDSC1000430-1200T by γ = 0.75 granules

● Smooth guide rail and scraper with self-cleaning function ensure smooth operation of equipment and less material residue. ● The discharge door can be installed in any position, and can be manually, pneumatically or electrically controlled to achieve multi-point discharge, discharge clean and thorough, no residue. ●With scraper chain tension detection device to ensure the normal operation of the equipment. ● The tail of the machine is a floating adjustable structure, and is equipped with an automatic cleaning device for the accumulated material at the tail to eliminate residues. Model slot width (mm) maximum output (t/h) remarks TGSS2525020-25 sleeve bending plate conveyor chain TGSS3232020-100TGSS4040030-150T

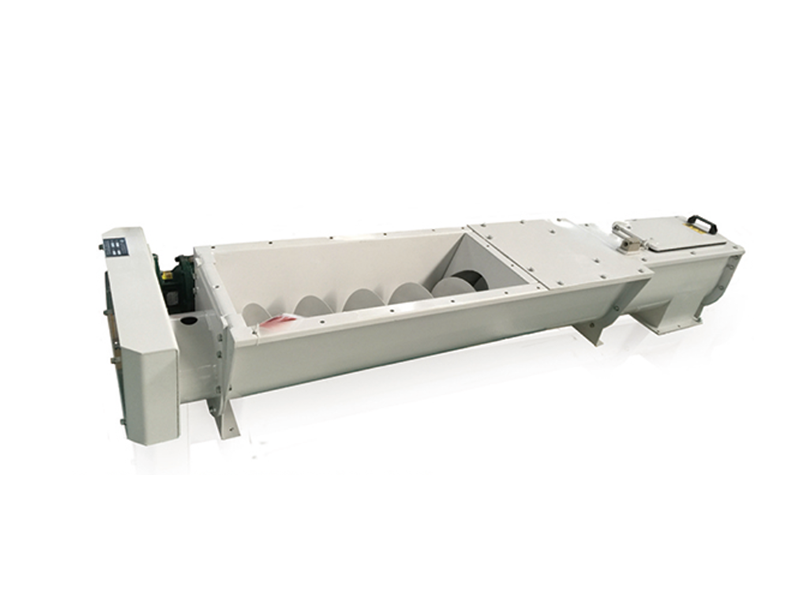

TLSU Series Trough Screw Conveyor

● trough type shell, suitable for the level of powder or granular materials or small angle of transport. ● Conveying without dust and odor. ● Equipped with anti-blocking operation door. ● Adopt gear reducer direct drive or chain drive, transportation balance, reliable, long life. Model Power (KW) Corn Yield (t/h)TLSU2001.1-5.55-10TLSU2501.5-7.510-12TLSU3152.2-1118.32TLSU4003-1529-70

TLSG series tubular screw conveyor

The sealing structure is reliable, clean, hygienic and no residue. ● Special feed inlet design, materials do not arch, fast cleaning door maintenance, easy to clean. The middle hanging bearing wear resistance is good, no maintenance. Modular design, can be arbitrarily extended and combined, up to 12 meters. ● Strong conveying performance, suitable for conveying, distribution and unloading of multiple feed ports and discharge ports. Model power (KW) powder output (t/h)TLSG1000.75-32-3TLSG1600.75-43-4TLSG2000.75-5.55-7TLSG2501.1-7.510

● European technology, self-cleaning structure. ● The head wheel adopts a "glue insertion" structure, which can quickly replace the "rubber strip". ● Adopt anti-deviation and anti-crushing tail wheel. ● The head is equipped with a replaceable wear plate to improve the service life. ● The machine head comes with explosion-proof port, high safety. ● Optional anti-reverse, speed measurement and anti-deviation devices. Rubber-inserted head wheel anti-deviation, anti-crushing tail wheel model pellet output (t/h) powder output (t/h) power (KW)TDTG40/1811-2911-222.2-5.5TDTG40/2312-3912-292.2-7.5TDTG40/2

TBLY circular pulse dust collector

●The use of tangential centrifugal air intake is beneficial to reduce the resistance of the wind network and reduce the load of the filter bag. ● Increase the height of the equipment and extend the length of the round bag, thereby increasing the filter area of the bag and improving the dust removal effect. ● According to the needs of the site, the use of dust collector and unloader combination, compact structure. ● Can have cone, flat bottom two kinds of discharge form for choice. Model bag specification (mm) filter area (m2)TBLY9Φ120 *

TBLF Series Square Pulse Dust Collector

●Widely used in grain, food, feed, light industry, mining, building materials, wood processing and other industries of dust removal and dust recovery operations. ● High-efficiency dust removal equipment, dust removal rate ≥ 99%, large air volume, small footprint, low equipment noise. ● The quick-release structural access door is adopted, which is convenient and quick to remove the cloth bag. The cage joint form adopts threaded connection for easy installation. ● It can be equipped with "drain waterfall mouth" to prevent dust explosion. Type bag length (mm) filter area (m2) filter air volume (m3/h)TBLF-4L12002.3550TBLF-6L12003.4820TBLF-18

TCXT series permanent magnet cylinder

● Mainly used for separating magnetic metal inclusions in raw materials, suitable for feed mills, grain and oil processing plants of various sizes. ● The magnetic core is made of the newly developed rare earth permanent magnet material, the magnetic induction intensity reaches 3000 Gauss, and the shell is made of all stainless steel. ● It has the characteristics of beautiful appearance, high iron removal efficiency, no space, no power, etc. Model powder output (t/h) pellet output (t/h)TCXT151015TCXT202030TCXT253550TCXT305570TCXT4080100

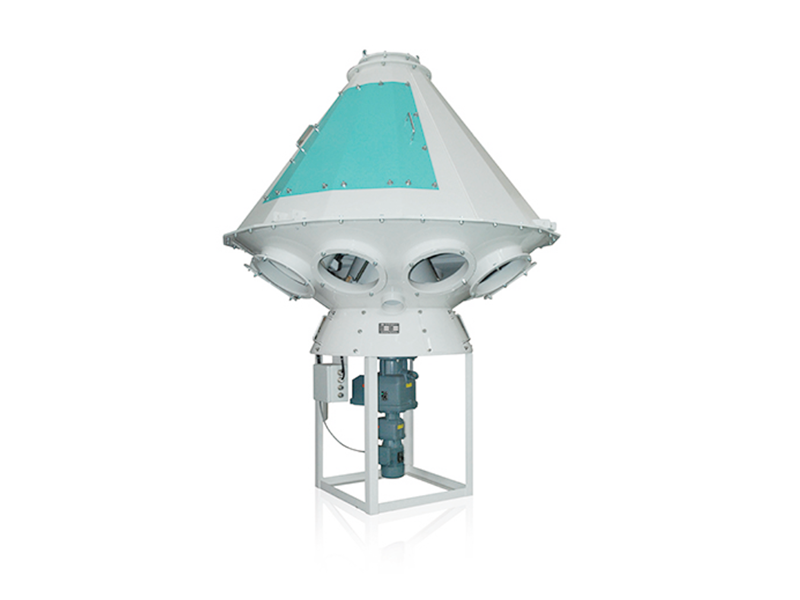

TFPX Series Rotary Distributor

●Conical structure, with access door, easy maintenance. ● The positioning of the discharge pipe is accurate and reliable, avoiding the material from the warehouse. ● The blanking pipe mouth and the dust suction pipe mouth are equipped with cleaning brushes, which can automatically clean the dust in the cleaning machine and keep the dispenser clean. Model power (KW) powder output (t/h) pellet output (t/h)TFPX-40.554060TFPX-60.554060TFPX-80.554060TFPX-100.754060TFPX-120.754060TFPX-141.14060TFPX-161.14060

STFZ series feeding port vibrating screen

● Novel products, used for the removal and cleaning of manually fed materials. ● The sieve body is equipped with a vibration motor. By selecting a reasonable mesh number and exciting force, the material can pass through the screen at a smooth speed, and the material can be manually cleared out of the machine at regular intervals. ● Both sides of the feeding door are equipped with gas springs, which are reliably sealed and do not leak dust. ● Feeding mouth general and low noise pulse dust collector combination, so that the feeding mouth environment more environmentally friendly and humane. Model Power (KW) Output (t/h)STFZ750.125-15STFZ1000.1210-30STFZ1200.215-40

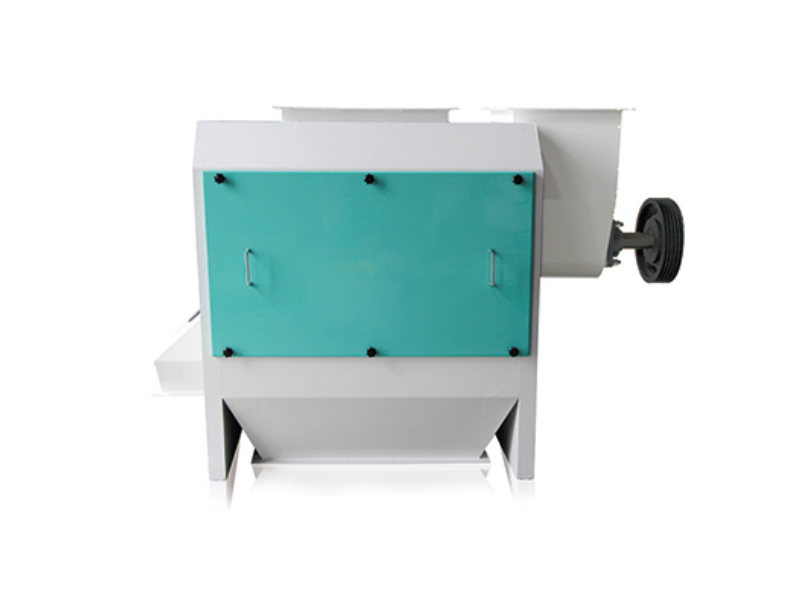

SQLB series powder insurance screen

● It is applied to the cleaning and separation of powdery materials, and can also be used to clean and break up lumps of powdery materials. ● According to the characteristics of the material matching appropriate screen, in order to achieve the best cleaning effect. ●The feeding section is an oblique chute structure with simple structure and large output. ● Gear reducer direct drive, low noise, long life. Model Power (KW) Output (t/h)SQLB7001110-50SQLB9002240-80

SQLT series powder cleaning screen

●Applicable to the cleaning process of powder raw materials. ● According to the characteristics of the material matching appropriate screen, in order to achieve the best cleaning effect. ●The feeding section is spiral forced feeding, and the internal screen cylinder changes the traditional conical structure to a straight structure, with a larger screen area and more convenient screen change. ● belt drive, low voice, smooth operation. Model Power (KW) Output (t/h)SQTL605.510-25SQTL901120-50

Address: No.99, Zhuhai Avenue, Dai Bu Town, liyang city, Jiangsu Province

E-mail: 707523086@qq.com

Mobile: 13301496060

Fax: 0519-87363939

Copyright©2024 Liyang Sanjiu Machinery Co., Ltd. ALL Rights Reserve.