Products

Products

Products

SFSP Series Horizontal Disc Crusher

● Rotary top feeding, with conveyor, high degree of automation; ● Adopt built-in widened rotor, super-thick wear-resistant hammer piece, with uniform crushing particle size; The use of serpentine spring coupling, transmission torque, damping effect is remarkable; ● It can not only crush bales of grass, but also crush messy grass, with a wide range of applications; ● Selection of high quality imported SKF main bearings, long life; ●Using high balance precision rotor, smooth transmission, low noise.

Special granulator for forage grass

● mainly applicable to hay, beet residue, straw and other coarse (fiber) feed processing. Such as wheat straw, rice straw, peanut skin, sorghum straw, sunflower seed shell, rice shell, coffee shell, corn straw, carob, cotton waste residue, wine residue, olive residue, peanut skin and other agricultural by-products rich in crude fiber. However, they must undergo appropriate pretreatment, such as fermentation, adding sodium hydroxide and other processes to obtain good granulation performance. ● This machine is equipped with a variety of aperture and compression ratio between 2-30mm flat die to choose from ● Users can choose flat dies with different aperture box compression ratios according to different needs, and the obtained technology and experience

SFSP series horizontal forage grinder

● The crusher is especially suitable for large-scale coarse crushing of bales of perfalfa, licorice, ryegrass straw and other forages, with high crushing efficiency and low production cost; ● Side full width feeding, with a high degree of automation conveyor; ● Adopt built-in widened rotor, ultra-thick wear-resistant hammer, uniform crushing size The use of tire type coupling, transmission torque, vibration reduction effect is remarkable; ● Quick-opening access door is convenient and quick to change screen and clean up; ● Selection of high quality imported SKF main bearings, long life ●Using high balance precision rotor, smooth transmission, low noise.

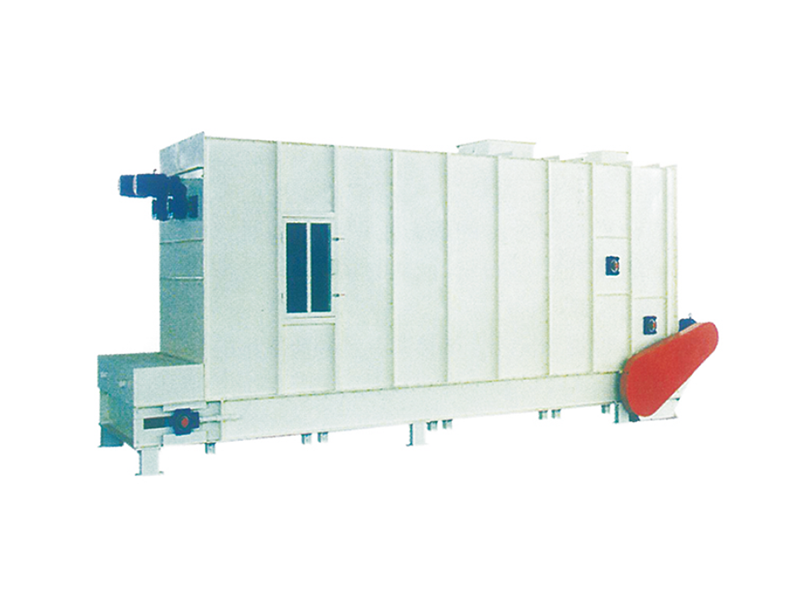

● This machine is the forage block section of the cooling equipment, high yield, low energy consumption, stable and reliable work, a wide range of applications, block, granular and other forage products can be applied; ● Novel design and reasonable structure; The use of frequency control transmission, according to the need to adjust the cooling time to ensure better cooling effect; ● Conveying with stainless steel, long life; ●Can effectively separate the finished forage from the bulk forage ● Bring its own material scraper to simplify the process layout. Output: 4-12 t/h power: 1.1 0.75/1.1*2 0.75w

●The machine has absorbed the advantages of international forage metering warehouse, with novel design, reasonable structure and beautiful appearance; ● Horizontal twisted dragon to transport incoming material to the rear side, compaction The work is stable and reliable, and the conveying capacity can be adjusted according to the needs; The use of variable frequency speed motor reducer, the discharge speed stepless adjustable; ●Forced discharge roller shall be used for discharging, and the two rollers shall be arranged staggered to ensure uniform discharge; ● Provide a uniform mixing field to obtain uniform grass blocks to ensure uniform feeding of the briquetting machine; Model main motor power production capacity MYZC100.55 2*2.2 2*2.13-5MYZC200.55 2*3 2

●This machine is the key equipment for the production of forage briquettes. It has the characteristics of high output, good performance, low energy consumption, low noise, and beautiful appearance; ● wide range of application, suitable for pressing light weight of forage, plant branches and leaves, straw and other materials; ● Adopt frequency conversion speed control feeding, feeding auger adopts special anti-blocking structure, high reliability; ● Using single pressure roller form, large intake angle, excellent briquetting performance, large volume of pressing chamber; ● Equipped with a number of liquid to add the nozzle, you can add molasses, cellulase and other nutrients. Model Main Motor Power Production Capacity SYKH51075/90/1102-5SYKH680

Address: No.99, Zhuhai Avenue, Dai Bu Town, liyang city, Jiangsu Province

E-mail: 707523086@qq.com

Mobile: 13301496060

Fax: 0519-87363939

Copyright©2024 Liyang Sanjiu Machinery Co., Ltd. ALL Rights Reserve.