Products

Products

Products

TBLY circular pulse dust collector

●The use of tangential centrifugal air intake is beneficial to reduce the resistance of the wind network and reduce the load of the filter bag. ● Increase the height of the equipment and extend the length of the round bag, thereby increasing the filter area of the bag and improving the dust removal effect. ● According to the needs of the site, the use of dust collector and unloader combination, compact structure. ● Can have cone, flat bottom two kinds of discharge form for choice. Model bag specification (mm) filter area (m2)TBLY9Φ120 *

TBLF Series Square Pulse Dust Collector

●Widely used in grain, food, feed, light industry, mining, building materials, wood processing and other industries of dust removal and dust recovery operations. ● High-efficiency dust removal equipment, dust removal rate ≥ 99%, large air volume, small footprint, low equipment noise. ● The quick-release structural access door is adopted, which is convenient and quick to remove the cloth bag. The cage joint form adopts threaded connection for easy installation. ● It can be equipped with "drain waterfall mouth" to prevent dust explosion. Type bag length (mm) filter area (m2) filter air volume (m3/h)TBLF-4L12002.3550TBLF-6L12003.4820TBLF-18

TCXT series permanent magnet cylinder

● Mainly used for separating magnetic metal inclusions in raw materials, suitable for feed mills, grain and oil processing plants of various sizes. ● The magnetic core is made of the newly developed rare earth permanent magnet material, the magnetic induction intensity reaches 3000 Gauss, and the shell is made of all stainless steel. ● It has the characteristics of beautiful appearance, high iron removal efficiency, no space, no power, etc. Model powder output (t/h) pellet output (t/h)TCXT151015TCXT202030TCXT253550TCXT305570TCXT4080100

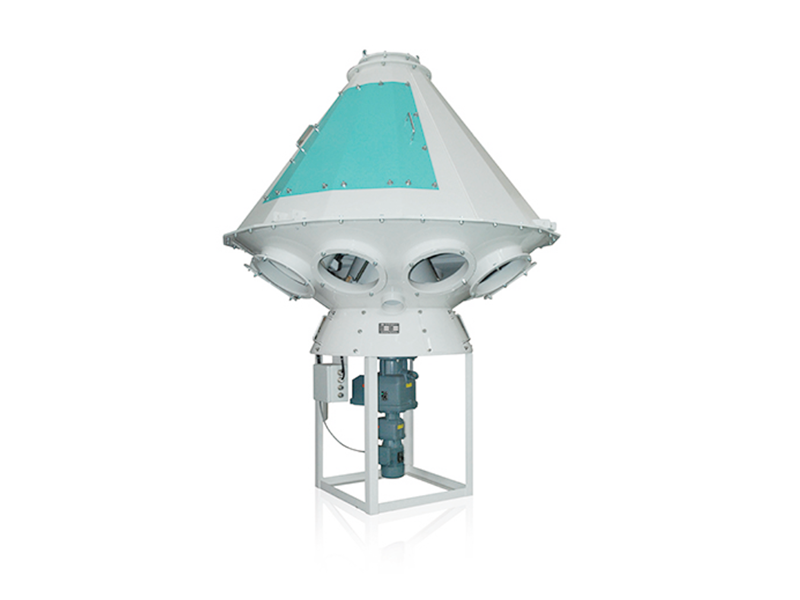

TFPX Series Rotary Distributor

●Conical structure, with access door, easy maintenance. ● The positioning of the discharge pipe is accurate and reliable, avoiding the material from the warehouse. ● The blanking pipe mouth and the dust suction pipe mouth are equipped with cleaning brushes, which can automatically clean the dust in the cleaning machine and keep the dispenser clean. Model power (KW) powder output (t/h) pellet output (t/h)TFPX-40.554060TFPX-60.554060TFPX-80.554060TFPX-100.754060TFPX-120.754060TFPX-141.14060TFPX-161.14060

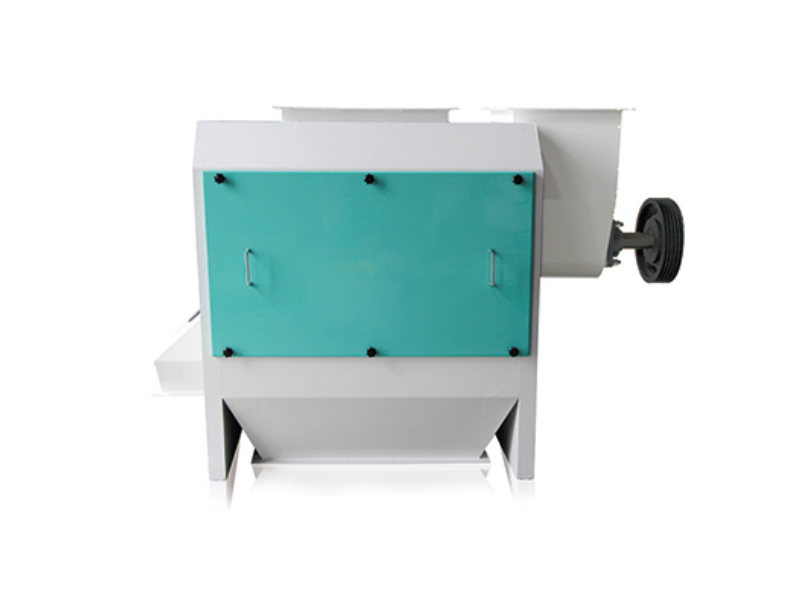

STFZ series feeding port vibrating screen

● Novel products, used for the removal and cleaning of manually fed materials. ● The sieve body is equipped with a vibration motor. By selecting a reasonable mesh number and exciting force, the material can pass through the screen at a smooth speed, and the material can be manually cleared out of the machine at regular intervals. ● Both sides of the feeding door are equipped with gas springs, which are reliably sealed and do not leak dust. ● Feeding mouth general and low noise pulse dust collector combination, so that the feeding mouth environment more environmentally friendly and humane. Model Power (KW) Output (t/h)STFZ750.125-15STFZ1000.1210-30STFZ1200.215-40

SQLB series powder insurance screen

● It is applied to the cleaning and separation of powdery materials, and can also be used to clean and break up lumps of powdery materials. ● According to the characteristics of the material matching appropriate screen, in order to achieve the best cleaning effect. ●The feeding section is an oblique chute structure with simple structure and large output. ● Gear reducer direct drive, low noise, long life. Model Power (KW) Output (t/h)SQLB7001110-50SQLB9002240-80

SQLT series powder cleaning screen

●Applicable to the cleaning process of powder raw materials. ● According to the characteristics of the material matching appropriate screen, in order to achieve the best cleaning effect. ●The feeding section is spiral forced feeding, and the internal screen cylinder changes the traditional conical structure to a straight structure, with a larger screen area and more convenient screen change. ● belt drive, low voice, smooth operation. Model Power (KW) Output (t/h)SQTL605.510-25SQTL901120-50

SQLY series granule cleaning screen

● Applicable to the initial cleaning and finishing process of granular raw materials. ● The cleaning effect is good, the impurity removal efficiency is high, and the impurity removal rate is greater than 98%. ● Adopt gear reducer direct drive, compact structure, smooth operation, low failure rate. Model Power (KW) Output (t/h)SQLY630.5520-50SQLY950.5550-100SQLY1201.1080-120

High strength simplified inner wall vertical reinforcement, horizontal spiral undercut ribs, greatly enhance the strength of simplified, wind resistance, earthquake resistance, snow load capacity. The simplified connection with good sealing performance is made of spiral edge bite, the thickness of the edge bite is five times that of the cylinder, the sealing performance is good, and it is convenient for fumigation and insecticide. The construction period is short. The construction period is short. It only takes 56 days to build a steel plate warehouse with a capacity of 1,000 tons. It can be put into use as soon as possible and create benefits for users as early as possible. Beautiful appearance The silo roof is conical in shape, which is not easy to accumulate dust and water, and the silo body has line flow. Long service life Simplified adopts hot-dip galvanized coil system, and the top of the warehouse is all treated with zinc technology, which has strong resistance and long service life.

In the construction of a variety of warehouse type, mechanized bungalow warehouse as a province of investment, short construction period, strong adaptability of the warehouse type, and is widely used. The mechanized bungalow warehouse has a relatively high degree of mechanized operation, saving manpower, good versatility and high working efficiency. Using fixed conveying equipment, scrapers and the like can be used to liquidate and leave the warehouse for materials with poor fluidity. The grain output at the bottom of the warehouse can be designed into two or more lanes, with less surplus grain. The surplus grain can be completed by means of a warehouse outlet or forklift. Due to the low grain loading height, the quality can be better protect, at the same time reduce energy consumption.

High precision a full set of the introduction of international leading processing equipment and technology to effectively ensure the accuracy of processing. The high degree of automation can achieve a high degree of mechanization and automation of high production efficiency, saving a lot of labor. The warehouse-making range can be made with a wide range of warehouse capacity. The single warehouse capacity can reach more than 15000 tons), with complete supporting facilities and complete functions, which can meet the warehouse-making requirements of different customers. Convenient maintenance adopts standardized, serialized and universal galvanized pot plates and accessories, superior replacement performance, convenient maintenance and easy to realize capacity increase or migration. Compared with the reinforced concrete warehouse, the total selection price is about 30%-50% lower than the same period of last year, which greatly reduces the investment cost of users.

High strength is made of hot-dip galvanized substrate color steel plate, with good shock resistance and no maintenance. It can be used for more than 20 years with good thermal insulation. Spray or roll-stick thermal insulation materials on the inner wall of the arch as required, which can meet the needs of different users for thermal insulation. The node with good sealing performance adopts mechanical bite seams, does not need bolt connection, is airtight, and is constructed fast without water seepage. It takes only 2-3 days to build an arched warehouse of 1,000 square meters. It takes 2-3 days to complete the function and can be treated by lighting and installing ventilation caps according to user requirements. At the same time, the arched building also has the advantages of sound absorption, fire prevention, prevention, waterproof, insect prevention, etc.

Address: No.99, Zhuhai Avenue, Dai Bu Town, liyang city, Jiangsu Province

E-mail: 707523086@qq.com

Mobile: 13301496060

Fax: 0519-87363939

Copyright©2024 Liyang Sanjiu Machinery Co., Ltd. ALL Rights Reserve.