Products

Products

Products

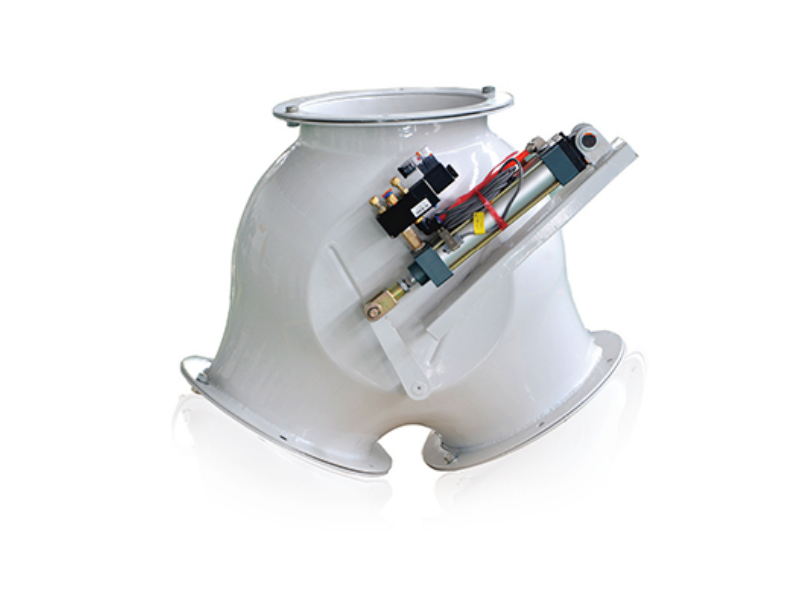

TBDQ series pneumatic round tee

● Domestic initiative, the overall shape of the stamping structure, compact structure, no leakage of material. ●The material dividing plate adopts rotary structure. ● There are two forms of flange connection or hoop connection at the inlet and outlet. ● Turn plate and guide plate with thick wear-resistant material, long life. There are pneumatic, electric, manual and other forms to choose from. Model powder output (t/h) pellet output (t/h)TBDQ20020-3030-40TBDQ25030-4040-60TBDQ30040-6060-100

● Classic gear drive, imported bearings, oil seals, high transmission efficiency, large output. ● The ring die is installed with conical surface, which makes the replacement of the ring die more convenient and easy. ● Automatic lubrication and gap adjustment device: it can realize the automatic lubrication of the main shaft and roller bearing, and the automatic adjustment of the gap between the die and roller. ● can be equipped with a variety of conditioners, can meet the livestock, fish and shrimp feed good conditioning effect.

STZG series jacket conditioner

● Jacket steam insulation, extended design; ● The quenching and tempering time is long and the curing effect is good, which is suitable for the quenching and tempering treatment of aquatic materials and livestock and poultry materials. ● All parts in contact with materials are made of stainless steel. ● One, two and three layers can be selected according to the requirements of quenching and tempering. Model power (KW) output (t/h) remarks STZG3807.53-12 dispensing SZLH400/420 granulator STZG420114-22 dispensing SZLH520/558 granulator STZG4801510-30 dispensing SZLH680/760 granulator

● All stainless steel material, extended, full-length large door design. ● The cylinder is heated by jacketed steam, and the operating door is heated by "hot nail", which makes the curing time longer and more uniform, and the cleaning and maintenance are more convenient. ● Suitable for the production of suckling pig feed, teaching trough feed and aquatic feed. Model Power (KW) Output (t/h) Remarks STZR10007.5 33-12 SZLH400/420 Granulator STZR150011 34-22 SZLH520/558 Granulator STZR250015 45-30 SZLH680/760 Granulator

● All stainless steel production, suitable for ordinary livestock and poultry production. ● Elongated design, long curing time, good tempering effect. ● Full-length large door structure, convenient for maintenance and cleaning. Model power (KW) output (t/h) remarks STZJ3807.53-12 dispensing SZLH400/420 granulator STZJ420114-22 dispensing SZLH520/558 granulator STZJ4801510-30 dispensing SZLH680/760 granulator

● Classic biaxial blade structure, suitable for feed, food, chemical and pharmaceutical industries, mixing uniformity CV ≤ 5%. ● Increase the effective mixing volume, the variable range of filling coefficient is large, and the filling amount is increased by 40% compared with similar models. The assembled blade structure can easily adjust the gap between the blade and the cylinder, and can replace the worn blade. ● Full-length split discharge door, faster discharge and shorter mixing time. ● Access door with safety lock for easy cleaning and maintenance. Model Power (KW) Output (kg/batch)

SDHJ Series Single Shaft Mixer

● Unique "pear-shaped" cylinder with equal ratio of length and diameter realizes high-speed mixing. The mixing time of each batch is less than 90 seconds, and the mixing uniformity Cv≤ 5%. ● The paddle blade is an assembled structure, which can easily adjust the gap between the paddle blade and the cylinder. The streamlined cylinder, less rotating parts, and the full-length large opening structure make the residue of the mixer within 0.5 ‰%. ● Unique shaft end and door frame sealing device to ensure no material leakage. ● Access door with safety lock, with easy cleaning and maintenance. ● Selection of SKF bearings and imported seals, reducer selection of gear reducer, low noise, smooth operation, long life. Model Power (KW) Output (kg

SWFL series vertical micronizer

● Widely used in corn, wheat, fish meal, monosodium glutamate, glucose, drugs, such as ultra-fine grinding, the finished particle size can be adjusted in 40-200 mesh. ● Vertical shaft without sieve type crushing, compact structure; Optimized design of the winnowing classification system, the output than similar products increased by 40%. ● Unique hammer head, gear ring installation, replacement hammer head, gear ring more convenient. Model power (KW) output (t/h) output description SWFL11090/1102-495% over 80 mesh SWFL130132/1604-695% over 80 mesh SWFL150160/2006-895% over 80

● Patented product, wide multi-cavity structure, uniform material distribution, high crushing efficiency. ● The bottom of the crushing chamber is provided with a "U" type secondary crushing chamber, and is equipped with a "fixed knife" device, and the output and fineness are increased by more than 30% compared with ordinary crushing machines. ● Selection of imported SKF bearings, longer service life, low maintenance costs. ● It is especially suitable for fine crushing of fish feed, suckling pig feed, etc. Model power (KW) output (t/h)(φ 1.0 screen) output (t/h)(φ 3.0 screen) SWFP66 * 4030/37/452-45-8 SWFP66 * 8055/75/905-88-1

SFSP Series Drop Shaped Crusher

Suitable for feed, food, chemical, brewing and other industries of granular and powdered raw materials crushing. ● The crushing chamber is drop-shaped and the bottom is provided with a "U"-shaped secondary crushing chamber, which can effectively destroy the circulation and increase the output by 25%. ●The rotor has undergone a precise dynamic balance test and selected imported SKF bearings, with low noise, long life and low maintenance costs. Model Power (KW) Output (t/h) Feeder Model SFSP30055/758-12SWLY300SFSP40075/90/11012-20SWLY400SFSP600132/16020-30SW

● suitable for aquatic fish, shrimp feed after curing treatment, prolong the stability of feed in water (2-5 hours) ● The box body adopts a jacket structure, the outer rock wool insulation, the operation to the jacket through steam heating, with a safety valve, safe and reliable. ● Flexible discharge of hydraulic flap, soft action does not damage materials, clean discharge, no need to change production manual cleaning. The contact part with the material is made of stainless steel, and the service life is longer. Model Power (KW) Output (kg/batch) SWDG16 * 60.55 1.51-1.5SWDG20*200.5 1.51.5-2.5SWDG2

It is suitable for the cooling operation of granular and powdery materials, especially the cooling operation of expanded materials. ● Rotating uniform material mechanism (optional) can be set to make the material layer in the machine highly consistent and the cooling effect is better. ● The discharging mechanism adopts hydraulic flap discharging, the action is soft and does not damage the material, the discharging is clean, and no manual cleaning is required during production change. ● Top stainless steel material, can effectively prevent the accumulation of moisture at the top of the rapid corrosion, longer life. Model volume (m3) power (KW) output (kg/batch) SKLN16 * 162.51.1 0.554-6SKLN20*2051.1 0.55

Address: No.99, Zhuhai Avenue, Dai Bu Town, liyang city, Jiangsu Province

E-mail: 707523086@qq.com

Mobile: 13301496060

Fax: 0519-87363939

Copyright©2024 Liyang Sanjiu Machinery Co., Ltd. ALL Rights Reserve.